How NMU’s ‘Work Scholars’ program is helping power Marquette’s medical device manufacturing boom

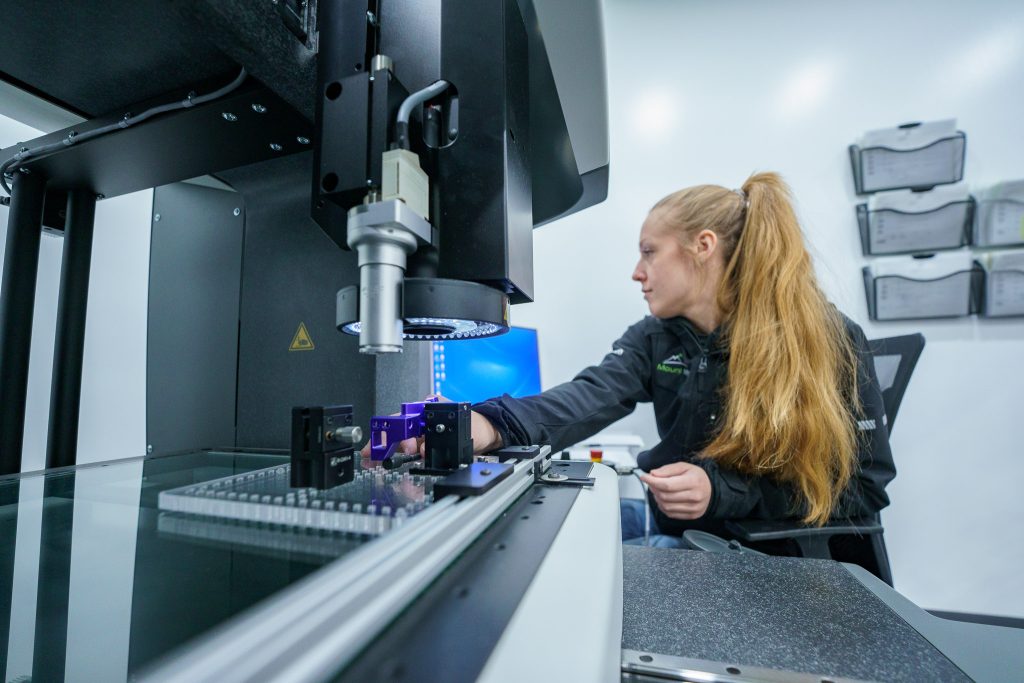

The university’s Work Scholars program provides a pipeline for students to earn a specialized engineering degree or certificate while gaining paid, hands-on industry experience before graduation.

A partnership between Northern Michigan University’s Engineering Technology Department and three area companies is strengthening Marquette’s position as a center of medical device manufacturing in the Midwest.

Made possible through collaboration with Able Medical Devices, Mount Mfg and EXALTA Group, the university’s Work Scholars program provides a pipeline for students to earn a specialized engineering degree or certificate while gaining paid, hands-on industry experience before graduation. The result is a cohort of skilled workers incentivized to stay and build a career in Marquette County.

David Nyberg, executive director of business engagement and economic development at NMU, said Work Scholars “was set up and coordinated by operations leaders at each of these companies, alongside Dr. Cale Polkinghorne, who is on faculty here at Northern, who helped to develop that framework …

“All of these companies are competitors for talent, but they all work collaboratively to develop programs like the Work Scholars program with our faculty,” Nyberg said. “They all sit down with interest and dedication, and support for Northern to help our programs grow because they all benefit from it as well.”

Work Scholars is the descendant of an earlier partnership between NMU and Pioneer Surgical Technology, a medical device company founded in 1992 by Marquette orthopedic surgeon Dr. Matthew N. Songer.

Under Songer, Pioneer worked with NMU to build a workforce development program centered on Computer Numerical Control, or CNC, and other skills crucial for high-precision manufacturing, supported by investments in equipment and hands-on training.

That effort successfully equipped students with practical skills and industry connections and, in many cases, full-time positions at Pioneer. It also led to the creation of several competitors, including Mount Mfg and the addition of many of the staff at what would become Able Medical Devices. Pioneer would later become Resolve Surgical Technologies before merging with two other global medtech companies to form EXALTA.

Dr. Cale Polkinghorne, an NMU alum and former Pioneer employee who oversees Work Scholars, said “the program at Northern was started strictly to teach people how to go into a machine shop and be able to operate machines.

“The majority of the talent on the machine floor at all three places came from Northern,” Polkinghorne said. “And I think that it’s safe to say that the majority of the people who use the CNC machines at all three places come from Northern and our little five or six person department.”

Adam Paltzer, Able’s vice president of operations, began his career as one of the first students to intern at Pioneer in the late 1990s.

He said, “I’ll give [Pioneer’s Chief Operating Officer] Steve Severson all the credit, because when he saw that we needed to grow fast, he immediately started working directly with Northern Michigan at that time.

“If you wanted to work for Pioneer Surgical, which was a very sought-after place to work, you went to school at Northern Michigan for two years, basically … And as you were in that program at Northern, you were working directly with our people and our engineers, and everyone. So you’re getting a taste of what we’re doing, you’re getting an education through Northern. And everyone was invested. Northern was invested. We were invested. The students were invested.

“And we created so many wonderful jobs and wonderful people that started learning this business — learning the machines, learning the regulatory path, understanding the quality concerns … We went from 30 people when I started to 300 people within 10 to 15 years.”

A combination of factors led the program to trail off in the 2010s, though former interns — many of whom had moved into engineering and leadership roles at other companies — remained aware of its potential.

When JM Longyear established Able as a subsidiary in 2017, one of the team’s first moves was to re-establish that relationship, opening the shop to interns and funding the purchase of two Swiss-turn CNC lathes for the university’s engineering department.

In 2023, NMU began formalizing plans to expand and name the program, later bringing Mount Mfg and EXALTA on board to pilot the newly christened Work Scholars.

In its current form, the program offers paid internships to engineering students pursuing two- and four-year degrees, as well as one-year CNC certifications. The hybrid approach empowers them to earn credit for work, be financially self-sufficient, and learn hands-on from supportive and industry-tested faculty and staff.

Jesse Nye, chief operating officer at Mount Mfg, said, “Let’s say that a high school student somewhere in the U.P. is interested in CNC machining as a career … while they’re at Northern, they can get into Able, Mount Mfg or EXALTA and actually have hands-on experience through Work Scholars through internships or otherwise.

And then when they graduate, they’re one year in, right out of high school, and ready for the workforce, making a good wage, having great benefits, excellent work environment, bright, clean, air-conditioned. This is very different than some of the other trades or one-year programs you can go into.”

Students considering a career in precision machining can anticipate an exceptionally strong job market.

Marquette County’s medical contract and OEM manufacturers have experienced rapid growth over the past few years, with Mount Mfg alone claiming a roughly tenfold increase in the size of its operations since 2020.

In October, Able opened a new 30,000-square-foot manufacturing facility in Marquette, with the potential to expand to more than 120,000 square feet in the future.

Paltzer said the skilled workforce generated by Work Scholars and its predecessor has fueled the area’s growth into a hotspot of the medical device industry.

“Once you start getting the talent pools together, the knowledge, it sticks together geographically,” Paltzer said. “That’s what’s happened to Marquette.”

“There are even more companies seeing what’s happening right now,” he said. “And if we keep investing in it and keep showing everyone what we are — If we can all work collectively together to show the country that this is a powerful medical device area, it can grow. And it can grow incredibly well.”